The RF-20-50 Liftable Cyclone Aerator is a new-generation high-efficiency aeration device developed based on traditional spiral aerators and integrated with multiple advanced structural designs.

Unlike conventional fixed-bottom aerators, which require draining the tank for installation and maintenance, the liftable cyclone aerator can be installed and serviced without emptying the wastewater tank, greatly reducing construction time and maintenance difficulty.

It features large service coverage, low air resistance, stable and reliable operation, anti-clogging performance, and long service life.

The product is widely used in industrial wastewater and municipal sewage treatment aeration systems, especially showing outstanding performance in wastewater with high suspended solids, high hardness, and scaling tendency.

Technical Details

Type: Liftable Cyclone Aerator

Model: RF-20-50

Service Area: 2–3 m² per unit

Air Flow Rate: 0.2–0.5 m³/min

Oxygen Utilization Rate: >20%

The RF-20-50 features a compact structure, with key components made of stainless steel. It is particularly suitable for wastewater tanks with limited space.

Thanks to its liftable design, installation and maintenance can be carried out directly from the surface without draining the tank, significantly improving operational convenience.

The aerator offers large coverage, low operating resistance, stable performance, non-clogging operation, and a service life exceeding 10 years.

It has been successfully applied in coal chemical wastewater, petrochemical wastewater, papermaking wastewater, chemical fiber wastewater, and landfill leachate treatment, with numerous proven project references.

Key Features

Unique Cyclone Structure

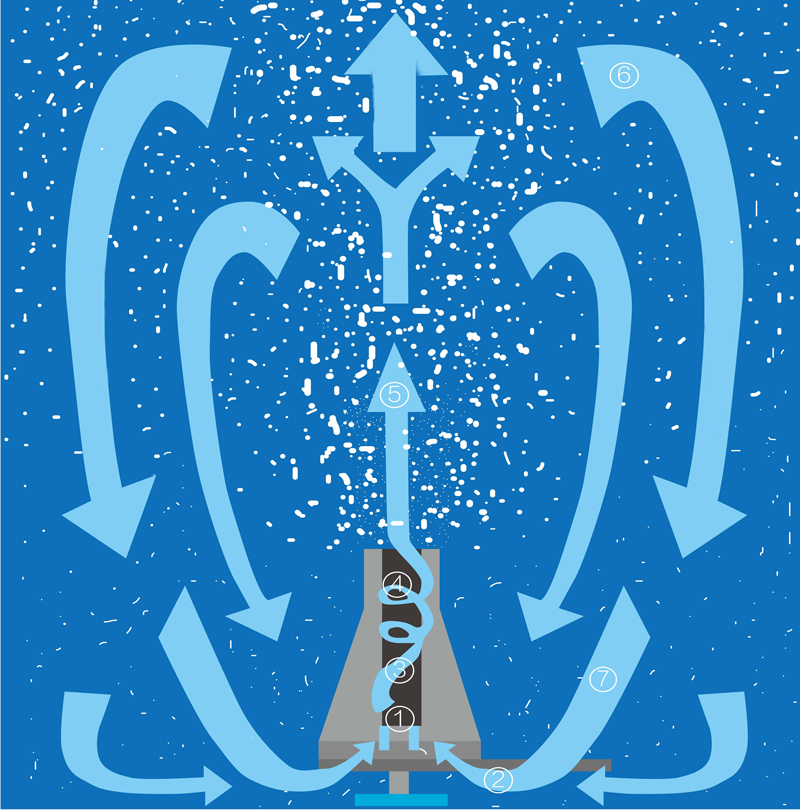

Air is discharged upward from inside the aerator, driving surrounding water to flow upward simultaneously. This creates both aeration and strong vertical circulation, ensuring no oxygen dead zones in the aeration tank.

Multi-layer Air Cutting Design

The internal mushroom-shaped multi-layer cutters divide airflow into fine bubbles without increasing air resistance, enabling thorough gas-liquid mixing and improving oxygen transfer efficiency.

Non-clogging, Maintenance-free Operation

The internal structure prevents blockage under both continuous and intermittent operation conditions.

Large Flow Channel Design

Particularly suitable for wastewater with high suspended solids, high hardness, and scaling properties. Service life exceeds 10 years.

Strong Mixing and Sludge Lifting Effect

During air discharge, a strong vacuum forms at the bottom, lifting settled sludge upward together with airflow, achieving full mixing and preventing sludge accumulation.

Liftable Design for Easy Installation & Maintenance

Installation and servicing can be performed without draining the wastewater tank, greatly reducing downtime and labor cost.

Applications & Advantages

The liftable cyclone aerator is suitable for:

Municipal wastewater treatment plants

Textile dyeing wastewater

Chemical wastewater

Coal chemical wastewater

Papermaking wastewater

Starch and alcohol wastewater

Food processing wastewater

Soy product wastewater

Other industrial wastewater treatment projects

For wastewater with high salinity, high oil content, high hardness, and scaling characteristics, the cyclone aerator demonstrates significantly better performance compared to conventional aeration systems.

It can also replace existing aerators directly without modifying original air pipelines, ensuring short installation time and reduced project cost.