The RF-40-130 Stainless Steel Liftable Cyclone Aerator is a new-generation high-efficiency aeration device developed on the basis of traditional spiral aerators and integrated with multiple advanced structural designs. Key components are manufactured from stainless steel, significantly extending the service life of the equipment.

It features large service coverage, low air resistance, stable and reliable operation, non-clogging performance, and long service life. The product is widely used in industrial wastewater and municipal sewage treatment aeration systems, demonstrating outstanding advantages in wastewater with high suspended solids, high hardness, and strong scaling tendencies.

Product Features

The RF-40-130 stainless steel liftable cyclone aerator offers the following advantages:

a. Full-tank circulation

Its unique structural design allows the water beneath the aerator to flow upward together with the air stream, eliminating oxygen dead zones throughout the aeration tank.

b. Multi-layer air cutting system

The internal multi-stage cutters ensure thorough gas–liquid mixing and fine bubble generation, effectively improving oxygen transfer efficiency.

c. Non-clogging and maintenance-free

The aerator remains free from blockage under both continuous and intermittent operating conditions.

d. Large flow channel design

Especially suitable for wastewater with high suspended solids, high hardness, and scaling characteristics, with a service life exceeding 10 years.

Performance Parameters

| Item | Unit | RF-40-130 |

| Service area | m² | 5–7 |

| Air flow rate | m³/min | 0.5–1.5 |

| Pressure loss | kPa | 0–1 |

| Oxygen transfer capacity | kg/h | 3–6 |

| Oxygen utilization rate | % | 20–25 |

| Power efficiency | kg/kWh | >5 |

| Installation water depth | m | >4 |

| Material | – | 304 / 316L / 2205 + ABS |

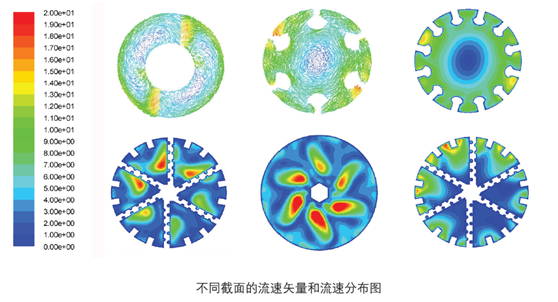

Computational Fluid Dynamics (CFD) Simulation

To ensure optimal performance, extensive testing and analysis have been conducted on various parameters, including air inlet configuration, water inlet design, and cyclone angle.

During product development, a large number of experimental tests were carried out for different cyclone aerator models. Based on these experimental results, detailed computational fluid dynamics (CFD) simulations were performed. Through three-dimensional modeling, key parameters such as:

Internal flow velocity

Gas–liquid mixing condition

Pressure distribution

Oxygen concentration distribution

were thoroughly analyzed.

On this basis, the aerator structure was optimized and improved multiple times. Field tests under real operating conditions further confirmed high oxygen transfer efficiency while maintaining extremely low pressure loss.

The figures below illustrate part of the simulation process.

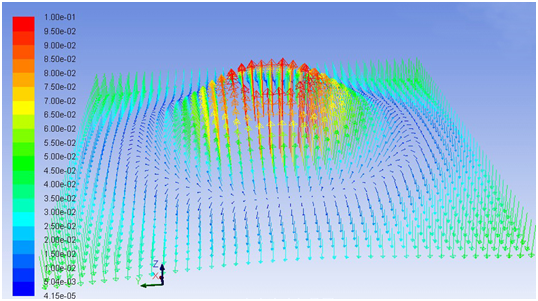

Flow Field Optimization and Circulation Analysis

Based on the CFD results, the optimal structural configuration of the cyclone aerator was determined.

Further simulations were conducted to analyze the aerator’s operating condition in water, including:

Upward flow velocity distribution

Downward flow velocity distribution

Overall circulation pattern in the tank

(Notes: Arrow length represents flow velocity magnitude — longer arrows indicate higher velocity; arrow direction represents flow direction.)

The simulation results clearly show a strong upward flow in the central area above the aerator and significant downward flow near the edges, forming an effective large-scale circulation within the tank.

This circulation pattern ensures excellent mixing performance and uniform oxygen distribution throughout the aeration basin.