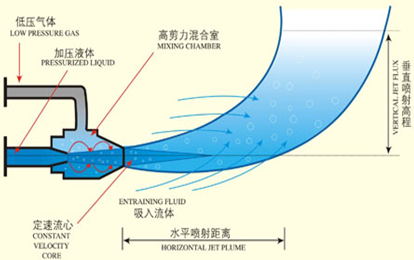

The jet aerator is an aeration device positioned between conventional bubble diffusion systems and mechanical aerators. During operation, liquid is discharged at high velocity through the internal nozzle. Due to jet turbulence and energy exchange, the liquid strongly entrains and mixes with air in the outer chamber, enabling rapid transfer of oxygen from the gas phase to the liquid phase with high oxygen utilization efficiency.

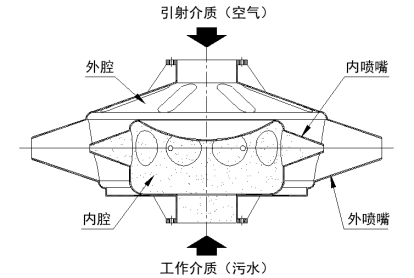

The RJ-10 Disc Jet Aerator mainly consists of an inner chamber, outer chamber, dual nozzles, liquid inlet, and air inlet.

Working Principle

The jet aerator operates by discharging liquid at high speed through an internal nozzle. The resulting jet turbulence and energy exchange create intense mixing with the air in the outer chamber, allowing oxygen to be transferred instantaneously from the gas phase into the liquid phase.

As a result, the jet aerator achieves high oxygen transfer efficiency, combining the advantages of both fine bubble aeration and mechanical mixing systems.

Application Areas

The Disc Jet Aerator enhances oxygen mass transfer efficiency through jet-induced turbulence and diffusion. It is widely used in biological treatment systems for industrial wastewater, especially in SBR (Sequencing Batch Reactor) processes.

Product Features

When used in combination with a blower and a circulation pump, aeration (oxygen supply) and mixing can be controlled independently.

Particularly suitable for integration with SBR processes for chemical wastewater treatment.

Capital investment cost is comparable to that of cyclone aerators.

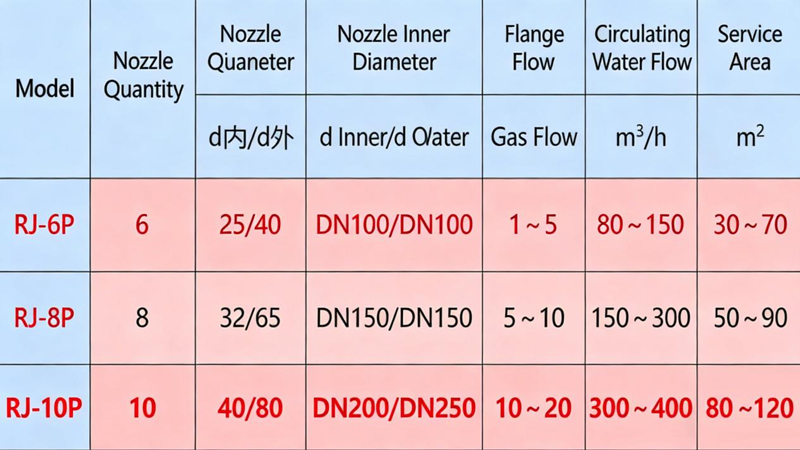

Performance Parameters